Triple Offset Butterfly Valve Series 4210 Catalogue

| Features and Benefits |

New Lotoke District HeatingTriple Offset Butterfly Valve design is recommended for Russian district heating applications requiring reliable zero-leakage, PN25,butt weld,bi-directional sealing in 270 degree water or steam conditions of critical processes, steam isolation, and temperature extremes within co-generation (combined heat power) systems, available in carbon and stainless steel the valves are designed for durability to provide low life time costs.

New lotoke largest butterfly valves are 1600mm nominal bore, butterfly valves can be specified with all-metal seal to make better sealing than laminated seal (stainless steelgraphite seal) butterfly valves.

| Structure and Benefits |

Unique Float Seat:

Unlike position-seated laminated sea valves, the Un ique Float Seated New lotoke bidirectional seal triple offs et butterfly valve self-adjusts to evenly distribute sea l compression. A floating seat and wide seal ring supporting face yield a BETTER SEAL to eliminate bin ding and to enhance performance.

Removable Sealing:

New lotoke district heating triple off set butterfly valve `s s eat and seal ring all can be removed easily when be damaged at accidentally, the sealing parts can be renewaled at short time, and REDUCES EQUIPMEN T MAINTENANCE TIME.

Metal-to-Metal Sealing:

The precision machined metal seat and seal ring de liver reliable and bi-directional shutoff in high-tempe rature, highpressure and severe service application s among others. The right-angle conical seat design facilitates an almost FRICTION-LESS IN-LINE SEA LING.

Innovative Shaft Seal Design:

Permits superior FUGITIVE TIPBV CONTROL (ISO 15848) under recurrent thermal cycling, and REDU CES POTENTIAL DOWN TIME.

| Design Features |

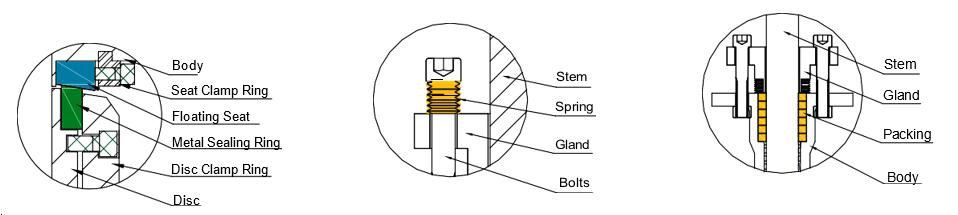

Sealing Ring Detail

■ Disc sealing ring is forged metal ring. When fully opening, the scour of medium at high speed will not damage the valve, which prolongs the working life.

Gland Spring Detail

■ Dynamic seal structure makes long-ter m seal of packing to extend the maintenan ce-free period.

Packing Detail

■ Fish scale combination packing system,Which ensures Valve Maximum leaka ge rate Less than or equal to 20ppm.

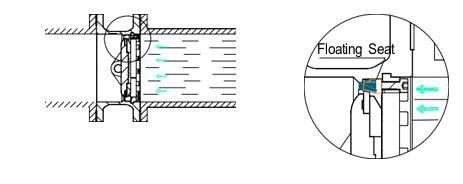

What is Floating Seat?

|  |

| Positive Seal: sealing ring engage to the Seat. | Reverse seal: seat engage to the sealing ring after microscopic displacement |

| Product Overview |

Materials of Construction

• Body: A105

• Disc: WCB/CF8M

• Stem: SS420/17-4PH

• Seat: F6a Hard coating

• Seal ring: F316 Hard coating

Size Range

DN (mm) | NPS (inch) | Pressure |

PN25 | ||

100 | 4 | • |

150 | 6 | • |

200 | 8 | • |

250 | 10 | • |

300 | 12 | • |

350 | 14 | • |

400 | 16 | • |

450 | 28 | • |

500 | 20 | • |

600 | 24 | • |

700 | 28 | • |

800 | 32 | • |

1000 | 40 | • |

1200 | 48 | • |

1400 | 56 | • |

1600 | 64 | • |

Temperature Range

• -84℉ up to 797℉

-29 degree up to 425 degree

Body Configurations

• Buttweld

Compliance

• Valve design standard: API609

• End to end dimension standard: API609/EN558-1

• BW connection standard: ASME B 16.25

• Test standard: API598

Test Pressure

• Shell Test Pressure: 3.75MPa

• Positive Test Pressure: 2.75Mpa

• Reverse Test Pressure: 2.5Mpa

• Positive and Reverse Air test Pressure: 0.6Mpa

Applications

• A District HeatingTriple Offset Butterfly Valve sho uld be used when the application requires reliable zero-leakage, abrasion resistance, bidirectional se aling, long-life.

Popularni tagovi: triple offset butterfly valve series 4210 catalogue, China, manufacturers, factory, customized, wholesale, price, cheap, in stock, for sale, free sample

Pošaljite upit